Service Hotline

+86-13758206140

Related articles

30L per day liquid nitrogen generator for animal husbandry

On-site liquid nitrogen generators

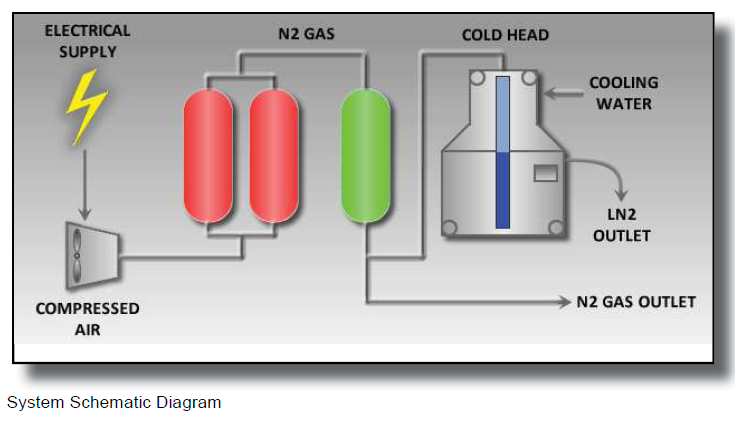

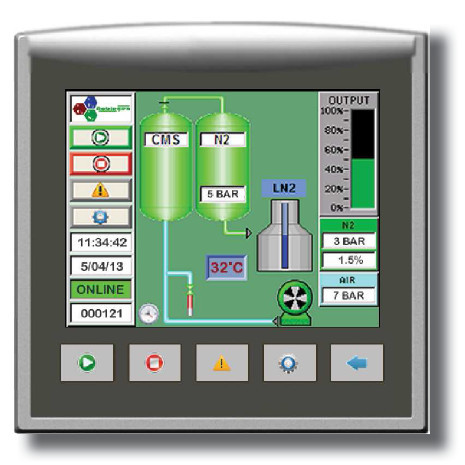

The Noblegen LN2 liquid nitrogen plants are a simple plug and produce LN2 solution. An internal PSA nitrogen generator combined with a cryo-cooler, helium compressor and internal dewar all controlled through a colour graphic HMI touch-screen gives a fully auotmated system at the touch of a button.

THE NITROGEN LIQUIFIER

The Noblegen LN2 liquid nitrogen plant is based on the Gifford-McMahon technique of a cold-head design with the compression and expansion of helium to obtain low temperature cooling. The liquid nitrogen generator are specifically designed for applications where a certain gas must be liquefied and transferred to an internal storage vessel which can then be dispensed to the application.

PRODUCT FEATURES

Internal oil-free air compressor with autoclave (anti-bacteria) suction filter.

PSA nitrogen gas generator to give -60°c pdp nitrogen gas.

Sterile filter on nitrogen gas line to cryo-cooler.

Reliable low maintenance helium compressor unit

Cryo-head is part of the dewar assemby for efficiency of production.

Liquid nitrogen outlet valve and transfer hose provided.

ADVANTAGES

Produce your own Liquid Nitrogen and eliminate deliveries.

Less waste – cold head keeps the dewar cold and reduces boil off compared to standard dewar.

Efficiency - Once internal dewar filled the system goes into standby, saving power.

Cost - Liquid nitrogen produced around 1/3rd the cost of delivered LN2.

Cleanliness – Closed loop system of nitrogen PSA, cryo-cooler and sterile filter ensures internal dewar is only filled with clean dry nitrogen gas and produces clean / pure liquid nitrogen.

APPLICATIONS

Liquid nitrogen injection into biological storage Dewar in IVF industry

Cryosurgery - removal of skin lesions

NMR spectrometer - keep liquid helium cool and prevent evaporation

Food packaging - fast cooling of fresh food

Blood and stem cells

Animal husbandry - preservation of semen of cattle, sheep, pigs and other animals

Metal treatment - metal protection during annealing

Drips - drips liquid nitrogen into a bottled drink to maintain proper pressure

Liquid nitrogen physiotherapy - deep cold sauna

Aerospace

Superconductor

Theme Park

Film making

Remote areas - such as underground, high mountains, islands, ships, etc. where liquid nitrogen is needed

Some domestic customers use site

Xinjiang Tarim University

Chinese Academy of Medical Sciences

INSTALLATION

The SCALA liquid nitrogen generator plants is a complete automated system supplied as a packaged piece of equipment either inside a floor mounted enclosure or a small skid mount design.

Firstly the cooling water should be connected to the ports shown on the side of the system – this should either be a mains water supply or a closed loop chiller specified and supplied by SCALA.

The liquid nitrogen plant can be situated in its preferred location and connected to the mains supply using the cable supplied.As the system has already been fully commissioned and tested at our factory the START button on the screen can be pushed in order for the system to go into an initial start-up sequence:

1. PSA liquid nitrogen generator achieves <1.0% oxygen content (approximately 30 mins).

2. The helium compressor / cold-head reduces the internal vessel temperature in order to start producing liquid nitrogen (approximately 4 hours).

Liquid nitrogen will be produced at the flow per day indicated on the data sheet for the specific product until the internal storage vessel is full. When full the generator will go into standby and will automatically re-start once the storage volume has dropped to pre-determined level.

LEVEL CONTROL

The internal liquid nitrogen storage vessel has a liquid level indicator with high and low set-points. The low level set-point can be adjusted by the customer for maximum efficiency depending on how much liquid is required, this means once the storage is full the system could remain in economy for longer and save power.

Technical Data

| Model: | LN30B-AC |

| Liquid nitrogen production : |

30 litres/day (1.25 litres/hour) at normal pressure 40 liters/day ( 1.67 liters/hour) at booster pressure |

| Dimensions: | 1.2m (L) x 0.6m( W) x1.8m( H) |

| Built-in Dewar tank capacity: | 100 litres |

| Voltage input optional: | Single phase :200 v,220v,230/240v 50Hz,220v 60Hz |

| Power consumption: | 3.0 kw @50Hz /3.4kw @60Hz |

| Helium compressor cooling: | Air cooled |

| Ambient temperature range: | 4°c to 32°C |

| zui High altitude: | 3000 meters, optional higher altitude |

| Compressed air requirements: | Built-in oil-free air compressor |

| Noise: | <60 dBA @1 metres |

| Control system: | HMI color graphics touch screen |

| High/low level in tank: | 0-100% |

| Liquid nitrogen pressure: | 1 bar g (1.5 bar g relief valves) |

| Main features: | Dewar vacuum protection system with alarm oxygen analyzer |

| Certification: | Dewar - EN 13458/97/23/EC; machine - CE /ISO9001:2008 |

Maintenance:

1. The drying tube should be replaced regularly. When 50% of the discolored silica gel in the drying tube changes color, the internal packing should be replaced. Replacement method: turn off the power and vent the system gas (the pressure drops to zero). Unscrew the purification tube in the direction indicated by the arrow, unscrew the end cap of the purification tube, and replace the silica gel desiccant.

2. The liquid nitrogen generator material processing method, the color-changing silica gel is baked in a 120 ℃ oven for 12 hours. The molecular sieve is burned in a muffle furnace at 250°C-300°C for 24 hours.

3. When replacing the desiccant, you should pay attention to putting all the absorbent cotton into the tube to ensure that it has no effect on the sealing end face, so as to ensure that the end cap can be sealed after being tightened.

4. Tighten it in the direction indicated by the arrow during installation, use soap to check for leaks after starting up, and ensure the seal.

5. It is not allowed to wrap various sealing tapes on the thread surface of the drying pipe without authorization, otherwise the drying pipe will be cracked and cannot be sealed.

6. If electrolyte is consumed during work, distilled water should be refilled regularly according to usage conditions to ensure that the liquid level is between the upper and lower limits.

7. Work does not consume KOH, but it is recommended to replace the electrolyte every six months. When replacing the electrolyte, first take out the waste lye from the liquid nitrogen generator of the instrument, add distilled water, start the instrument, and let the system clean the electrolysis system for about 5-10 minutes. Pump out the distilled water and add the prepared new electrolyte lye.

8. The displayed value of the flow is changed according to the current loaded on the electrolytic cell. There may be slight changes in vibration. The displayed value changes within ±10 within the normal range, but the flow supply can still output stably.

Hot Tags: 30L per day Liquid nitrogen generator for animal husbandry, manufacturers, suppliers, factory, buy, price, for sale, wholesale, customized, China, made in China, cheap, discount, low price

Hangzhou Scala Filtration Technology Co.,Ltd

Main: compressed air filter,air water separator, liquid nitrogen generator

Fax:

Email: sales@scala-filtration.com

Address: Room 110,Building 1, Kaiyuan Yisu, Liangzhu Street, Yuhang, Hangzhou, Zhejiang, China

©2024 Hangzhou Scala Filtration Technology Co., Ltd. Record number:浙ICP备15045093号-6 Login Sitemap